High Feed End Mills - Steels up to 45 Rc - Metric - Variable Pitch - Reduced Neck

High Feed End Mills

The specifically engineered end profile of this fully stocked offering of metric, High Feed End Mills reduces cutting forces, while its reduced neck geometry provides maximum strength in long reach and deep pocketing applications.

- Specifically engineered end profile for optimal tool engagement and reduced cutting forces

- Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics

- Geometry proven to achieve maximum feed rates in steels up to 45 Rc

- Reduced neck provides maximum strength in long reach and deep pocketing applications

- End cutting geometry (non-center cutting)

- h6 shank tolerance for high precision tool holders

- Tplus coating offers high hardness for improved tool life and increased edge strength in difficult-to-machine materials

- Solid carbide end mills

- CNC ground in the USA

Advanced Search

| Cutter Diameter | Shank Diameter* | Length of Cut | Overall Length | LBS (Reach) | Neck Diameter | Flutes | Theoretical Radius** | Tplus Coated | Tool Description | Add to Cart | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 +.00mm-.05mm |

D2(h6) | L2 +.80mm-.00mm |

L1 +1.60mm-1.60mm |

L3 | . | # | Tool # | Price | |||

Running Parameters

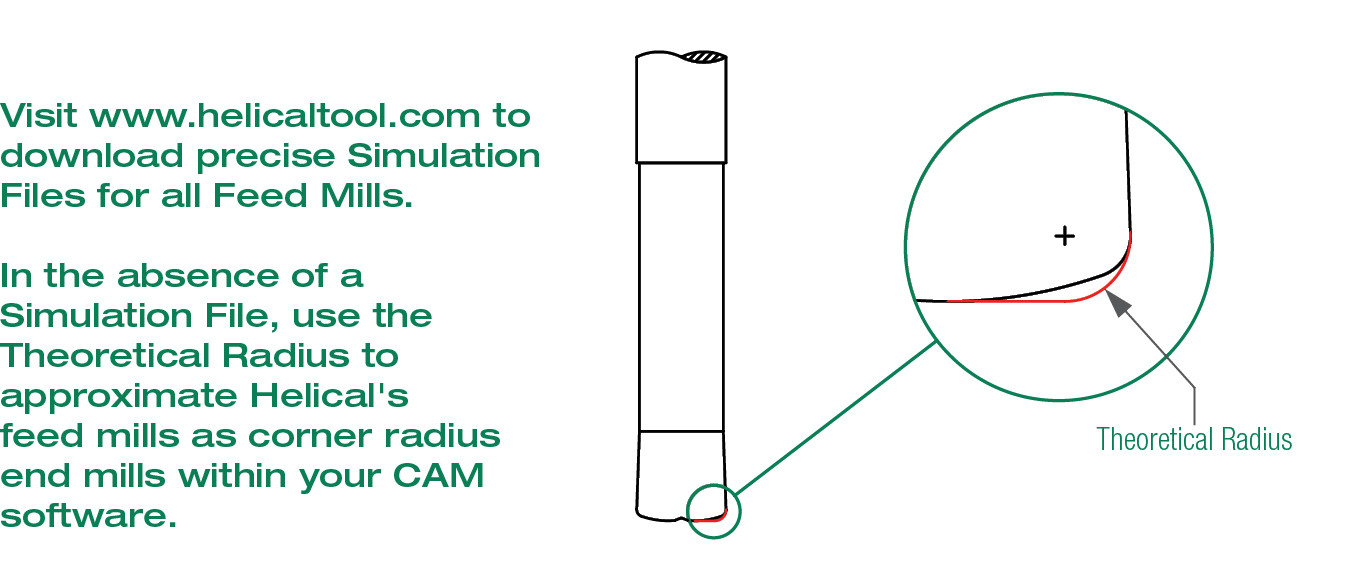

SIM Files / Tool Libraries

Write A Review

Thank you for your review. It has been submitted to the website administrator for approval

Please select a rating.

Write A Review

Thank you for your review. It has been submitted to the website administrator for approval

Please select a rating.