Browse By Product Name

Helical Solutions offers top shelf CNC machine tools that run faster, push harder, and machine smarter. Browse from End Mills for Aluminum and Non-Ferrous Materials; End Mills for Steels, High-Temp Alloys, and Titanium; and Chamfer Mills.

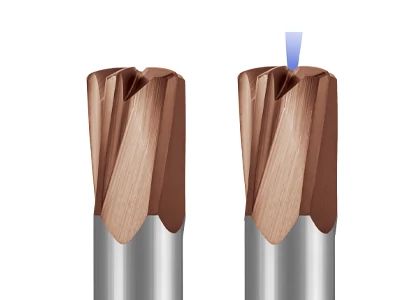

Nickel Alloys

Fully stocked and ready to ship today, Helical Solutions End Mills for Nickel Alloys are specially engineered to excel in Inconel 718 and other nickel-based superalloys. Offered in 6 and 8 flute options, these tools come coated with Helical's Tplus coating for high hardness, resulting in improved tool life and increased strength.

Aluminum & Non-ferrous Materials

Earn a competitive advantage in aluminum and non-ferrous materials by opting for material specific CNC end mills that are designed to deliver.

Steels, Tool Steels & Cast Iron

Helical Solutions' fully stocked offering of End Mills for Steels includes Roughers, 3 flute, 4 flute, 5 flute, 6 flute, 7 flute, and multi-flute end mills. These tools, all of which are available to ship the day of their purchase, are optimized specifically for steels, tool steels, and cast iron. Browse between several unique geometries, including chipbreaker and reduced neck styles.

Stainless Steels & High Temp Alloys

Helical Solutions End Mills for Stainless Steels and High Temp Alloys features end mills coated in Tplus, which offers excellent heat resistance and high hardness for reduced abrasion and extended tool life in these notorious alloys. Tools within this section include roughers, end mills of 4, 5, 6, and 7 flutes, and multi-flute products.

Titanium & Titanium Alloys

Helical Solutions End Mills for Titanium and Titanium Alloys includes roughers, 5 flute, 6 flute, 7 flute, and multi-flute tools. Included in this fully stocked product offering is the HVTI-6 End Mill for Titanium, our extremely popular 6 flute end mill engineered to provide higher metal removal rates (MRR) and 20% more time in the cut.

High Feed End Mills

Designed for high feed applications, High Feed End Mills take advantage of chip thinning with a specifically engineered end profile to increase machining efficiencies. Similar to High Efficiency Milling (HEM) techniques, the milling technique for these tools allows for drastically increased feed rates to maximize chip thickness and keep radial forces low.

Specialty Profiles

Helical Solutions offering of specialty profile tooling includes straight flute and helical flute chamfer mills, as well as Combination Chamfer/End Mills. These fully stocked tools ship the day of their purchase, ensuring that the special features your unique part requires are accomplished as soon as possible, with limited machining downtime.