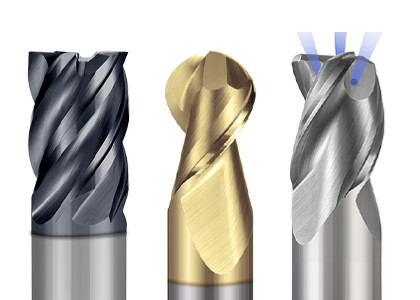

Browse By Tool Type

Helical Solutions products are fully stocked and ready to ship the day of purchase, ensuring that your machining downtime is minimized and your shop's efficiency is maximized. Our products are built to last and excel at aggressive running parameters, meaning you will experience greatly reduced cycle times, heightened productivity, and superior performance.

Aluminum & Non-ferrous Materials

End Mills that accelerate MRR and achieve a quality finish in aluminum and non-ferrous materials.

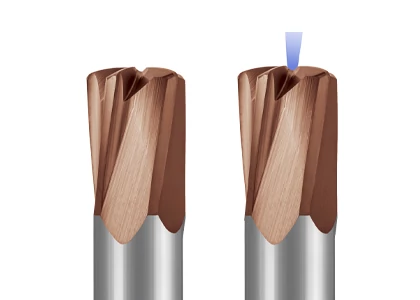

Coolant Through Tools

Reduced heat, enhance chip evacuation, and increased MRR with these high performance end mills.

Hardened Steels

Superior end mill offering that delivers in HEM applications of hardened steels over 60 HRC.

High Efficiency Milling (HEM)

Tooling that delivers faster feed rates, superior chip control, and reduced cutting forces.

Steels, Tool Steels & Cast Iron

End Mills for steels, tool steels, and cast iron, including Roughers and Multi-Flute Finishers.

Nickel Alloys

End Mills for Nickel Alloys engineered to excel in Inconel 718 and other nickel-based superalloys.

Multi-Axis Finishers

Helical Solutions Multi-Axis Finishers with a defined profile for massive reductions in cycle times.

Stainless Steels & High Temp Alloys

End mills coated in Tplus for excellent heat resistance and high hardness for reduced abrasion.

Titanium & Titanium Alloys

Offering for Titanium and Titanium Alloys, including roughers, 5, 6 , 7, and multi-flute tools.

High Feed End Mills

High Feed End Mills take advantage of chip thinning with a specifically engineered end profile.

Specialty Profiles

Helical Solutions fully stocks the products you need most for the specialty cuts your job requires.

Reduced Neck End Mills

Reduced Neck End Mills provide maximum strength in long reach and deep pocketing applications.