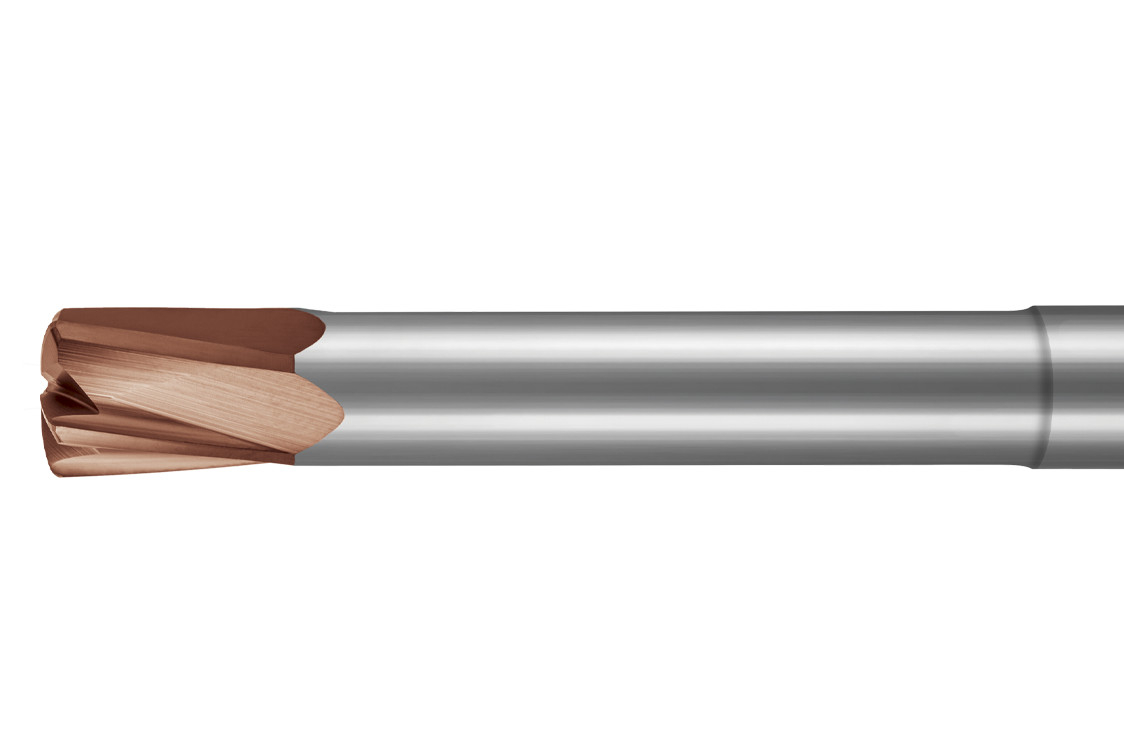

High Feed End Mills

Designed for high feed applications, High Feed End Mills take advantage of chip thinning with a specifically engineered end profile to increase machining efficiencies. Similar to High Efficiency Milling (HEM) techniques, the milling technique for these tools allows for drastically increased feed rates to maximize chip thickness and keep radial forces low.

Combination Feed & HEM

Combination Feed and HEM Mills for outstanding performance in a wide range of ferrous materials.

Aluminum

Helical's High Feed End Mills feature a reduced neck geometry for maximum strength in long reach and deep pocketing applications, and a unique end profile for optimal tool engagement.